Custom Injection Plastic Product Thermal Forming Plastic Part Injection Auto Part

Description

Basic Info.

| Model NO. | Injection Plastic Part |

| Package | PE Bag |

| Shipping | by Express, by Air, by Sea, by Train, by Truck |

| Payment Term | T/T, L/C, D/P, D/a |

| Lead Time | 10-15 Days Since Order Day |

| Sample | Free Sample |

| Insulation Resistance | 1000mΩ Min. |

| Fire Protection Grade | UL94V-0 |

| Application | Automotive Connector |

| Process Craft | Injection Molding |

| Color | Black |

| Operating Temperature | -40 to +105 |

| Raw Material | PA6t + 30% G.F |

| Transport Package | Carton |

| Specification | PA6T+30% G. F UL94V-0 |

| Trademark | FPIC |

| Origin | Shenzhen, China |

| HS Code | 8536909000 |

| Production Capacity | 200000PCS/Day |

Product Description

Custom Injection Plastic Product Thermal Forming Plastic Part Injection Auto PartWe, Shenzhen Forman Precision Industry Co., Ltd, provide one- stoped Custom Automotive Components solution. Mainly offer custom automotive connectors, precision plastic injection molding parts, Stamped Metal Parts etc. Product Description| Product Name | Custom Injection Plastic Product Thermal Forming Plastic Part Injection Auto Part |

| Raw Material | PA9T UL94V-0 |

| Color | Black |

| Operating Temperature | -40ºC to + 105ºC |

| Insulation Resistance | 1000mΩ MIN |

| Package | PE bag in Carton |

| Shipping | By Express,By Air,By Sea,By Sea,By Truck,By Train etc |

| Free Sample | available |

Custom Plastic Injection Molding Parts is one of our main production line. We have supplied our plastic moulding parts to Audi, Ford, Renault etc for years. If you have any demand for custom plastic parts, just send your drawing and detailed requirements to us , you will get the response ASAP. Just Try it. Thank you in advance. Ahout Forman

| Founded In | 1999 |

| No. of Employee | 241 members |

| Occupied area | 11000 Square Meter |

| R&D Team | 14 staff with know-how and more than 10 years experience in electronic and automotive industry |

| Main Business | Electronic Connectors, OEM/ODM Automotive Connectors , including high precision metal stamping parts, plastic injection molding parts etc |

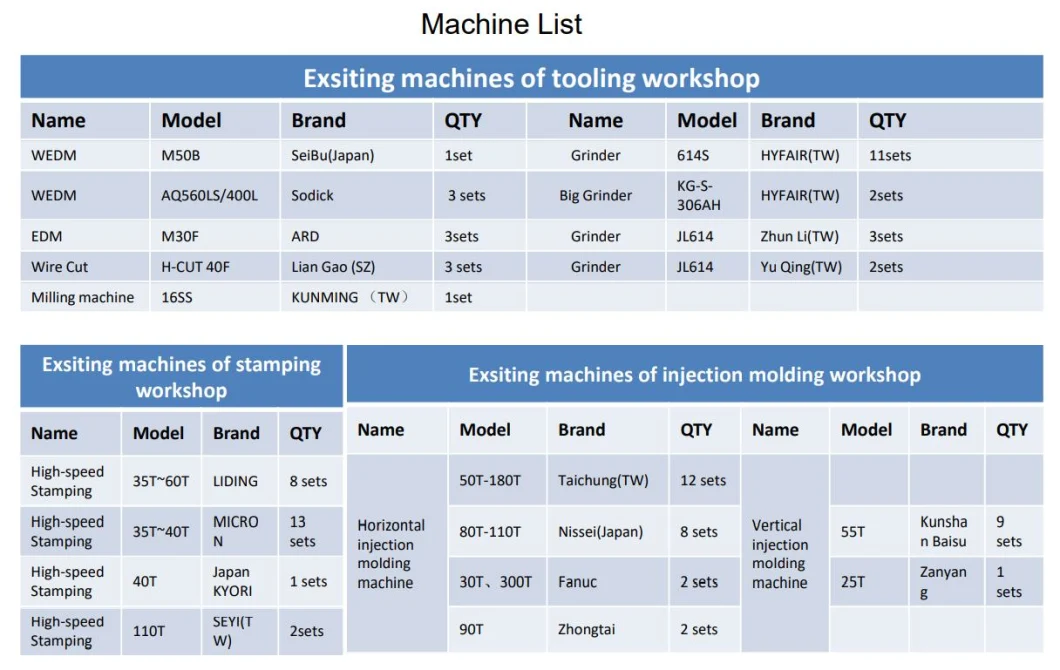

| Workshop | Four main workshop--Tooling machine workshop,Injection molding workshop, Metal stamping workshop and Auto Assembly Workshop |

| Machine List | Pls check the machine for each workshop as below: |

Our Office:

In order to Control the product quality in the whole process, FPIC built itsself lab equiped with kinds of professional inspection and testing machine. In this lab, we could in Salt spray resistance test ,tensile test,intersection detection, coating thicknessinspection and so on. Before delivered, all the products should be detected by CCD 100%,to insure its high performance.

Certification & Honor1999 Founded2004 ISO9001:2008 Certified2005 Became USB Association Member2006 First Full- Automatic Assembly Line2013 ISO14001 Certified2016 IATF 16949 Certified

ExhibitionShippingRegards to Shipping , it is up to you. By Express , By Air, By Sea, By Train, By Truck etc .

FAQQ: Are you trading company or manufacturer? A: We are factory, so we can provide competitive price for you. Q: What kind of products can you provide? A: Our company (FPIC) can provide OEM/ODM spare parts. We are an experienced OEM / ODM business, focusing on tooling and mass production of Stamping parts, Injection-molded plastic parts and Insert-molding components . Q: What's kinds of information you need for a quote? A: In order to quote for you earlier, please provide us the details together with your inquiry. 1. 3D drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF) 2. Material requirement (include contact material and insulation material.) 3. Surface treatment 4. Quantity or Consumption (per order/ per month/ annual) 5. Any special demands or requirements, such as packing, labels, delivery, etc. Q: What shall we do if we do not have drawings? A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order. Q: What makes you different from others? A.1. Our know-how R&D team with 14 member who all have rich professional knowledge and experience about connectors 2. Automated production equipment and matched quality testing equipment. Q: Is it possible to know how are my products going on without visiting your company? A: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress. Q: Can I have a trial order or samples only for several pieces? A: As the product is customized and need to be produced, we will charge sample cost, but if the sample is not more expensive, wewill refund the sample cost after you placed mass orders.Thank you very much for your patience . Any demand , just send your drawing and detailed requirements for our further confirmation. Have a nice day!

Our Contact